ORE SEPARATION BY SCREENING

Objectives:

One of the main reasons for the processing of minerals is to reach maximum value production of raw materials. There may be several goals in the processing of minerals, this may include a crushed product of a predetermined size and shape, or achieving the maximum recovery of metals from a very complex ore.

Originally, this mineral purity, whether metallic or industrial, indicates the value and price of minerals. All minerals are free to separate from each other, where at the first liberation by reducing size and size control has performed. Different methods can be used to separated minerals, most of which are selected according to the properties of the individual minerals.

1.0 Introduction:

Practice Using granular grinding ore material and separating it in specified and different sizes with specified particle size is called just screening and in a full name we call it mechanical screening. This process is called size control.

In fact, this is a size control process that helps us to better understand the process of separating solids into two or more other products based on size. We can also use optimal measurement or size control methods to improve the results related to the capacity, size and shape of the particles.

Therefore, it can easily be claimed that one of the very necessary step in the processing of minerals is Sizing or Ore Sorting. The sorting of minerals is that the separation method.

The process of separation is the same as separating the ore in its different constituent parts. Separation of ore today is used in many industries like industrial mineral mines, diamond mines, underground mines or precious metal mines and expensive mines.

For this purpose, the separation of ore in order to increase the efficiency of the purification or refining process is arranged by reducing the amount of material required for processing and increasing their purity significantly.

2.0 Size control:

To be able to get the right size for the final products, you cannot count on crusher or grinding mills because they are both not accurate enough.

The reason for this is the variety in mineral crystal compounds (hard-soft, abrasive – nonabrasive), in design and in the operation of the equipment. For this reason, the size control is used to improve size reduction in the process steps and in the final products.

3.0 Theory of Screening:

By screening, we can separated smaller particles from a granular substance particle when they are smaller than screen and separate small particle from larger particles. This is a complicated task, and it does not seem as simple as it sound and it is difficulties compound as the opening becomes smaller.

For example, if a sample of crushed ore contains 50% of the weight of particles smaller than 1.8 on a static test sieves, very small amounts of small pieces of small size remain on the screen and only trickle particles pass through it.

But when the minus 1/8 particles begin to pass through the screen, that the sieve subjected in some kind of reciprocating, motion or gyratory in the horizontally way or shake such a reciprocating motion, which includes vertical and horizontal movements. This will continue until it reaches a reduction rate, and until all particles are separated to a certain size

The shaking duration time of the sieve in order to reach this stage must be roughly proportional to the size of sample placed on the test sieve1, which the depth of the static material bed have to determines before the performing the shake.

3.1 Controlling factors of Screening:

The graph below shows the controlling factors for screening operations in mineral processing.

3.2 Particle size distribution

For many reasons, it is necessary to control the particle size distribution in a mineral processing plant. These reasons can be for any of the following reasons:

- In order to enable standardized materials to bypass from grinding or crushing circuit, and subsequently returning larger particles to perform particle size reduction operations to reach standard size

- In order to provide optimum particle size materials to achieve efficient processing in downstream and separation systems

- In order to provide a product that is proportional to the size of the particle size needed base on market needs.

Generally, either by screening or by using the classification of particle separation work is done on a size basis.

3.4 Particle Sizes and the Mesh Numbers:

4.0 Mechanical screening method:

A mechanical screening, generally known only as a screening, is one of the methods for separating materials using granulated ore materials, which disassociate materials in different amounts and in different particle sizes. Mechanical screening is used in a variety of industries, the most important of which can be mining and mineral, agriculture, food, recycling, pharmaceuticals, plastics, etc.

4.1 Types of mechanical screening:

In general, different types of mechanical screening equipment are used in various industries to separate materials. Often the difference between this types of screening is due to the movement of the device through the motor drive.

- Circle-throw vibrating equipment: This kind of mechanical screening works with an eccentric shaft that makes the shaker frame lurch at a given angle.

- Circle-throw vibrating equipment: This kind of mechanical screening works by using vibrating gear and a shaker and set of shaker where the drive movement the whole structure. At first, the structure extends to the maximum throw or length, and then reaches a base state.

Under the structure, there is a pattern of springs, where shaking and shock absorption are high and as the structure reaches the base state. Typically, this kind of mechanical screening with this type of structure is used for materials or particles at a very large size, sizes that measure the size of the pebble size to the boulder material.

- Vibratory equipment with high friction: In this type of screening, the screen is applied only on the cloth. Unlike the screening methods described above, the frame of the equipment is quite stable and only vibration is generated on the screen.

• Gyratory equipment: This type of mechanical screening is very different with the above methods. In fact, in this type of machine gyrates there is a circular motion at a level near the surface at a low angle. - Trommel screens: This screening method does not require shaking and the materials are fed to a horizontal rotating drum with screening panels around the drum diameter.

5.0 Screening:

A screening in a simple configuration has a level of hard perforated with a matrix of fixed dimension apertures. Materials are sent to the screening surface in such a way that materials of appropriate size fall from the aperture to the screen and the larger particles move to the end of the screen to evacuate.

Screening is usually less than 0.5 mm. It uses two screening work processes: screening using free fall and screening by stratification.

- a) Screening by stratification

In this way, a screen deck is created for materials bed, when the screening device starts to move, internal friction in materials is reduced and materials are stratified. This means that materials with finer particles or, with the right size, can pass through the particles of the larger ones and giving a sharp separation.

- b) Screening by free fall

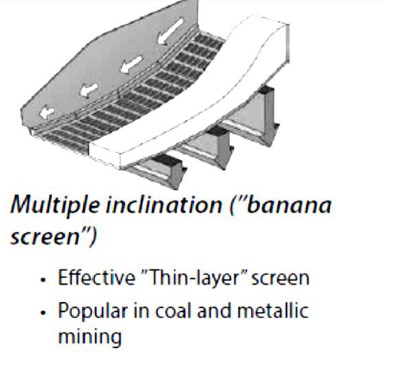

If our method is to classify the double inclination method (from 10-15 to 20-30 degrees), we use a free fall screening method. It means that no particle will be placed on the screen deck. In this method, the particles are measured directly through the screening media, which means they will have higher capacity (or a compact set), but the sharpness of separation will be less. This method is optimal when a large amount of fines is to be removed soon.

We said that screening is often done using a mechanical screening method. But there are several types of screening.

5.1 Types of Screen Media:

Care should be taken when selecting the screen for its correct size and the type of screen. In addition, screening media selection is also very important. Therefore, it is important to be careful when selecting two correct aperture factors related to the cut size and also the function of the screen wearer in selecting the correct screen.

Generally today various types of screening media are produced and sent to the market that use different materials in their production. But the two most common types of screen media media available on the market are tensioned and modular.

- a) Woven wire cloth :

Stainless steel is commonly used to produce Woven wire cloth. Woven wire cloth is used as a filtration medium for screening, and may vary depending on the industry, which has caused a wide range of Woven wire cloth in the industry.

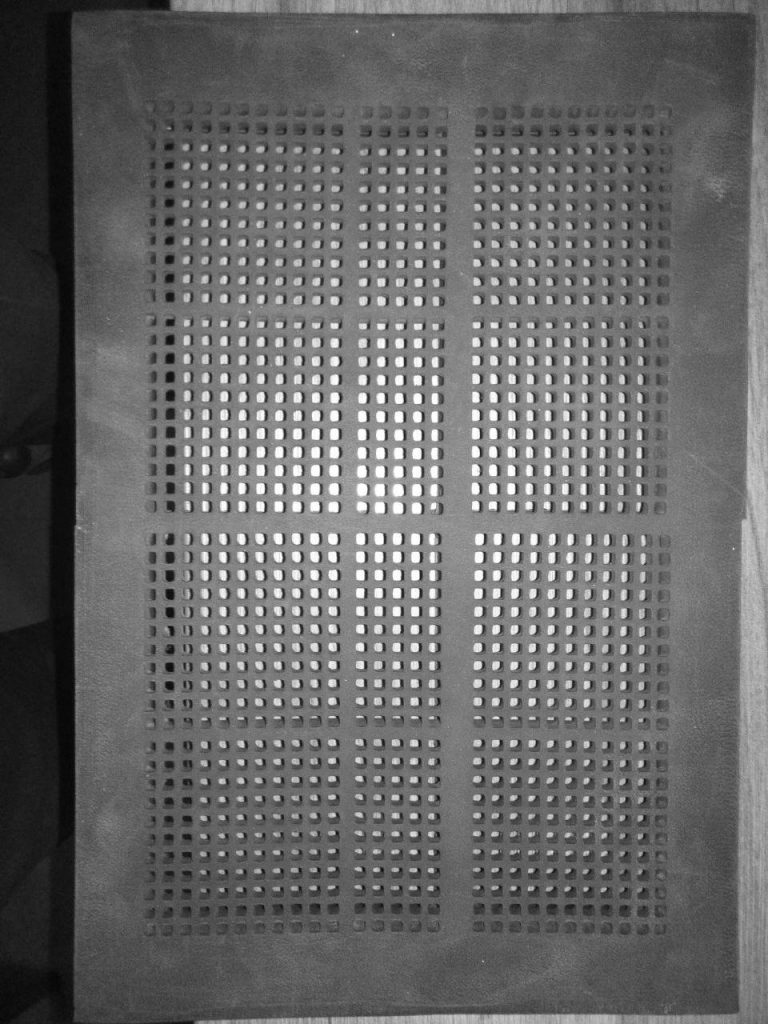

- b) Perforated & Punch Plate :

Perforated plates or punch plates are mainly used in crushing or screening plants on scalable vibration screens and after crude crops pass through grizzly bar. Punching plates are likely to be mounted on a tensioned deck, which results in very high wear and long life of the punch plates for high pressure applications and high flow of materials.

- c) Artificial or Synthetic screening media (mainly rubber or polyurethane)

Artificial or rubber screening media are used in places where the subject of wear is of great importance. Typically, this type of screening media is used in large quarries and mines or any other large producers, which minimizes the repetition of the line of production to repair the screen deck.

Whereas rubber is used as a high-impact screen media material for screening and is usually mounted on top deck of the screening scalper.

- d) Self-Cleaning Screen Media :

The reason for the unveiling and engineering of the self-cleaning screen media was initially to clean up the screen cloth blinding and clogging and pegging problems. The idea was to put the crimped wires together, side by side on a flat surface, create openings and then somehow place them together on the support bars (crown bars or bucker bars). This could lead to the wires being loosened and free for vibration between the support bars, preventing blinding, clogging and pegging of the cloth

5.2 types of Screen

Although screening samples are numerous and varied, we can generally classify them into four types.

More than 80 percent of the screenings used worldwide are of type single inclination, stratification screens. Double, triple, or multiple inclination are other types of screening. However, in some specific applications screening may be considered a combination of stratification and free fall.

6.0 The Process of Screening :

The vibration in the screening machine is carried out by a drive, the screening media performs the separation and classification of the particles, the media and the driver plate are embedded in the deck, and the vibration of the material is transmitted.

In fact, screening operations are performed using physical factors. For example, increasing or facilitate of cutting is done by vibration, g force, bed density and material shape. Using electrostatic force creates a barrier to water absorption in the screening and makes adhesion or attachment. Also, it can produce quite dry material by absorbing it into the screening itself. .

6.1 Physical principles of Screening

- Vibration that can be both sinusoidal and gyratory

- sinusoidal vibration usually occurs on an angled plate relative to the horizon. In fact, using the frequency and amplitude of the vibration, this vibration is generated in a wave pattern.

- A Gyratory vibration occurs near the surface of plane and usually occurs at low angles and in a reciprocal direction.

- Gravity: This physical interaction is actually after material is thrown from the screen causing it to fall to a lower level. At the same time, gravity pulls particles to be drawn through the screening media.

- Density: The stratification of materials according to their density

- Electrostatic force: This force is used when screening for materials or particles that are too dry or too wet.

6.2 General categories of screening:

Screening is either dry screening or wet screening methods. Depending on the type of screening, the material flow is separated into appropriate grades and then processed according to the grade of the product material as the final product or as intermediary product. The machines can also be divided into moving or static screening machines. And they can even be classified according to their horizontal type or their inclined.

7.0 Screening Equipment:

A drive to induce vibration, a screening media for particle separation, and a deck on which the media and the driver plate are embedded constitute the main structure of the screening machine, and are usually mode of transport for the vibration. Generally, mechanical screening equipment that perform separation work has different types.

A mechanical screening has a major equipment that are:

- Grizzy

- Trommels

- Other moving type screens.

7.1 Grizzly:

Grizzlies, mainly used in crushing circuits, are used for rough screening of coarse materials. In fact, Grizzlies use several heavy bars in parallel manner. On the inclined surface, of these bars and materials softer the coarse material slides than the spacing between the finer materials falls through. In the process, the Grizzlies vibrated to improve performance.

7.2 Revolving Screen (Trommel):

Trommel is a rotating cylindrical screen that is slightly inclined. With this screening, both dry and wet materials can be easily separated.

This involves feeding the material from one end of the cylinder, at which time materials of a undersize fall off the screen surface and larger or oversize particles are directed by rotating movement the device down to the discharge end.

Trommel have low capacity and are more prone to wear and this has reduced their cost. Shake or vibrate screens are mostly used instead of these devices.

7.3 Moving Screens (reciprocating, oscillating, vibratory and gyratory screens):

Reciprocating, vibratory, shaking or oscillating screening are the only typical examples of different types of horizontal inclined screening. The movement of the surface and the result of the diffusion on these materials determine the type of difference between these screening machines.

Among these, vibration screening is the most well-known type of screening device of its kind commonly used for various mineral processing applications.

Due to the different requirements for processing different minerals, different manufacturers have designed different vibration and motion screening systems depending on the size and type of particles for different mineral processing plants. In many screening machines, there are several decks that allow different products with different particle sizes to be obtained in a single feed.

The gyratory screen is designed to be able to move both gyratory and slight vertical on the screen deck. There are usually several decks for this type of screening machine that are interchangeable and removable.

Gyratory screening is commonly used to separate fine particles, while this type of screening can be used for both wet and dry materials.

7.4 Tumbler screening technique:

The Tumbler screening method is used to separate very small particles from particles larger than three-dimensional elliptical motion. In fact, this is one of the best ways to separate many types of materials in fields with raw materials and building materials for processing and reuse. Tumbler screening with its circular motion can achieve efficiencies above 99%.

Exceptional and unique rush design, high performance and durability, flexible angular velocity that the machine can achieve, etc. have made the Tumbler Screening Machine widely used these days and can be found in many industries.

Improved vibration, improved vibratory and improved linear screeners have made Tumbler screening work in an elliptical motion resulting in the production of very fine, uniform materials. In this way, the finer, smaller particles stay near the center and the larger particles move outward, just like Panning for gold.

8.0 Screen Capacities:

8.1 Vibrating Screen – Capacity Calculations

When calculating the capacity of the vibrating screens, the twelve factors used in the following formula must be taken into account.

They are

Formula: A = B * S * D * V * H * T * K * Y * P * O * W * F

“A”, the calculated capacity per square foot of screen area in tons per hour.

B = Basic capacity per square foot in tons per hour (One ton = 2000 pounds)

S = Incline factor

D = Deck factor

V = Oversize factor

H = Halfsize factor

T = Slot factor

K = Material condition factor

Y = Spray factor

P = Shape factor

O = Open area factor

W = Weight factor

F = Efficiency factor.

9.0 Factors Affecting Screen Performance

- a) Material Factors:

A variety of shapes, sizes, surfaces, densities and moisture levels can be found in particles in dry bulk materials. Keep in mind that all possible conditions should be considered when predicting screening performance, taking into account their impact on capacity in terms of the weight of the screening passage per unit area.

It should also be borne in mind that the combined effects on screening performance or screenability of particle shape, surface, surface texture, or internal moisture cannot exceed the density and size of these variables. In fact, more accurate information about their impact should be obtained using actual tests.

- b) Size and shape:

In general, all kinds of spherical, sculpted, angular, oval, scaly or tabular shapes can shape a separate individual granule.

As sawdust can be mixed into pieces of wood, these materials can also be mixed. In most screening programs, the size of the cut-off points is 4 to 325 ( 0018) mesh downward. The cut-off point is to determine the minimum particle size remaining on screening and to measure the maximum particle passage underneath.

- c) Density:

Depending on each material and its specific weight, the bulk density for each shape and size distribution is lb./cu. ft. (PCF) Screening is, in fact, a volumetric measure, although the capacity and amount of material passing through the screen is generally determined by considering a standard bulk density of 100 PCF , per unit weight and per unit time. Meanwhile, the actual rate of matter with different bulk density should then be adjusted at a ratio of 100 PCF.

- d) Moisture:

Both absorbed and adsorbed states can form the moisture in the granular particles. Both modes can make screening difficult, but the potential for internal moisture absorption is higher than for external moisture absorption.

In the presence of surface moisture, the adhesion of the particles results in resistance to classification.

Generally, the moisture content of the surface is allowed for dry screening, excluding inorganic particle components or a ranges of bone dry to open the underlying plates in the standard 20 mesh state, to 3% for 1.4 openings.

Also, the moisture absorbed in permeable soils such as clay can block the screening arms due to the accumulation of hard fins attached to the plate wires.

- e) Size Distribution:

The main characteristic that controls rate of undersize passage through screen opening is the distribution of particle size in a granular bulk material that for representative sample of the material, the materials that passage through a screen opening is larger than the smallest particle and smaller than the largest particle.

In fact, for size distribution using screening analysis, a series of standard wire mesh sieve screens are used, each with a standard Tyler scale of 7 standard scale and with a constant velocity speed of 1.05 “to 0.0029” (200 mesh) and The measurement is done. Size distribution is used as the percentage of weight of each fraction between successive sieves in a series.

If the weight on the y-axis is plotted against the average size of each segment on the x -axis, the result will be similar to a frequency distribution curve.

- Motion

In order for the screening to work properly, a relative motion must occur between the screen and the particle mass. Although the sieve remains specialized at times, but mainly in commercial screening programs, the particle mass must flow on the sieve, which requires some sort of mechanical movement.

The velocity of this mechanical motion actually determines the velocity of the volumetric particle mass flow on the sieve, and this motion is actually characterized by increasing both the current and the sub-sizes passing through the sieve.

Depending on the type of screening design, this can be done in different ways. The sieve can be done in a circular horizontal plane, the gyratory, with a vertical vibration swing on the circular motion, can be done with a harmonic motion in a straight line, the circular motion with vibration on the vertical plane, Can occur by vibration in a linear motion on a horizontal sieve that may have both general and horizontal components, or, eventually, the vibration in a vertical direction.

Whatever the motion, the desired velocity will be sloping because it needs to achieve the desired mass and usually moves between 40 and 100 fpm.

10.1 Motion in the Horizontal Plane (Shaking Screens)

The amplitude and frequency (rpm) remain constant in most screening that use horizontal plane motion employing motion designs. In fact, in horizontal motion designs, the vibrating particle mass rotates smoothly over the screening with not any bouncing, and this is the best opportunity for stratified undersize particles to classify and pass through openings, which is a major advantage in such designs. .

10.2 Motion in the Vertical Plane (Vibrating Screens)

Motion components in the vertical plane of 5.3 to 6 grams or more often indicate vibrational screening. Lifting and dropping causes the material bed to expand. Along with screening or reducing the chance to find and pass through an open space for single particles.

Of course, this is a disadvantage compared to slick horizontal motion designs, but on the positive side, it does work with normal natural force to allow particles of approximately the same size to get stuck in the crater. Therefore, this will resist progressive blindness and cause the turbulent and irregular expansion of the material bed in the packaging process.

11.0 The Screenability Characteristic

Two variables generally express the performance of each screening machine: first, the capacity, which is determined in units per ton or pounds per hour, and the second, efficiency, as previously described. The screening capability or Screenability refers to the essentially that measure the rate of stratification materials in a specific condition that must be separated in principle.

- 0 Conclusion:

Generally, there are many varied processing applications in some industries, including mining and mineral processing of screening. For example, once the minerals are extracted, they are transferred to the primary crusher, but before crushing a large boulder they must be placed on a shaker with a 0.25 in (6.4 mm) sieve shielding screen.

Once these large materials are crushed, the materials produced can pass through the screen openings or slots, and these slides or openers will continue to become smaller in size to convert as needed materials.

Finally, the final screening activity is to create the final separation for the production of saleable products with consideration of the size and grade required for the materials.