Liquid silicone rubber injection process (LSR)

The use of industrial rubbers to manufacture some of the parts and accessories used in the industry became popular in the mid-nineteenth century. Synthetic rubbers, such as silicone, were considered early on due to their higher resistance to heat, chemicals and acids, and later combined with other materials to make these rubbers much more durable. It also provides a place where it can withstand very high temperatures or the worst wear and tear.

Many parts of the industry today, especially those that require high resistance to acid, chemical or heat, are made of rubber and are used in a variety of industrial applications.

But making rubber parts has always been a challenge. With the advent of industrial molds, the manufacturing these parts make easier, and today processes such as the process of producing rubber parts with LSR molds or liquid silicone rubber have made it possible to produce rubber parts in bulk and in high quality.

What is Injection of Liquid Silicone Rubber or LSR?

Initially it was around 1970 that the use of liquid silicone rubber was used to make parts and products. In this process, it was enough to produce industrial molds only for the production of various part with liquid silicone rubber, for this reason, by injecting liquid silicone rubbers, easily produced a variety of products and parts. The LSR made a lot of difference and it quickly became a great alternative to other synthetic rubbers and even silicones themselves.

Previously, different thermoplasts were used to produce industrial part and accessories, but with the advent of LSR, other thermoplasts actually replaced with liquid silicon rubber.

Nowadays, liquid silicone rubber injection method is used to produce different types of parts used in different industries. The automotive, medical, construction, aerospace, mining and mineral industries are all part of this.

The biggest benefit of the components produced by the liquid silicone rubber injection method is the ability to produce very long to very low life parts, extremely high resistance and customize the components to suit the customer’s needs. For this reason, many component companies have used liquid silicone rubber to produce a variety of industrial molds for the wide range of components required using this type of liquids.

Characteristics of liquid silicone rubber (LSR)

Liquid silicone rubber has been used for large volume production for about 40 years now, and because the use of LSR has made it easier to produce and increase production volume and improve product quality, every day a wider range of products is moving towards the use of this technology. LSR’s capabilities are also constantly improving.

In general, the most important requirement for using liquid silicone rubber is perhaps the only industrial mold required today. Because having a perfect industrial mold can produce all kinds of parts with this material.

But the unique features of the LSR that can be used to produce a variety of components include the following:

- Eco-friendly:

LSR is a very environmentally friendly material and human tissue, and this has been proven by many experiments. This is because silicon is resistant to bacterial growth, and does not change color and corrosion. The use of LSR in the food and drug industries is also permitted, as it does not exhibit any specific chemical reactions and has no specific color or smell. For this reason, liquid silicone rubber is also approved by the US Food and Drug Administration (FDA). Experiments show that processes such as gamma rays, autoclaves, steam, ethylene oxide, etc. can sterilize the LSR, which permits its use in all industries.

- High reliability against heat:

LSR is also resistant to very high temperatures. For this reason, this material can also be used for the manufacture of high temperature components. Even some wall molds and wall materials are manufactured with LSR coatings to provide fire protection, and there is overall great confidence in the safety of this material.

- High Resistance to Chemicals and Acids:

One of the key properties of liquid silicone rubber is its extremely high resistance to chemicals, acids and bases.

- Mechanical properties of liquid silicone rubber:

LSR has excellent mechanical properties and has good elasticity. Parts made by this process can be easily cut, or stretched, and their high strength and hardness will prevent the quality of the parts after cutting or in stretching mode.

- Electrical properties of liquid silicon rubber:

Given that silicon is highly resistant to all kinds of temperature fluctuations and acts as a superconducting insulator, nowadays it offers a variety of electrical components and electrical impurities. They produce with LSR which is more reliable than other materials.

- Ability to produce parts in different colors:

Another feature of the LSR is that it is transparent and colorless. For this reason, it is possible to produce transparent and colorless parts or by adding color, produce parts in different colors.

Design of liquid silicone rubber (LSR) injection mold

Industrial molds are needed to produce all kinds of rubber parts and products. For this purpose, either ready-made industrial molds or industrial molds must be designed and manufactured for a specific process or product.

Generally, ready-made molds are for parts that have already been marketed, or that these parts are widely used in the market. Like all kinds of industrial gaskets used in industries such as pumps or centrifuges. Generally, industrial mold manufacturers consider and produce ready-made industrial molds, which are known as ready-made molds, given the constant use of these components.

But to produce parts and products that are designed, either exemplified in the market, or have undergone changes, new industrial mold design is needed.

Industrial piece mold design

Fortunately today, using the expertise of companies such as Jamin Tarhe Parsian (JTP), it is not difficult to use sophisticated designs to produce highly sophisticated components. The company’s specialists, using the latest and the best software, design the best industrial mold, tailored to the type of component and deliver it to the customer after testing and approval.

For the design of industrial molds specifically for liquid silicone rubber injection, although some mold production processes are in accordance with the industrial mold of other injectable components, and are in fact plastic injection molds, these molds must be much more durable and stronger, To be made with stronger and more effectiveness parts and materials. Because they are going to produce more durable and effective parts. To make this type of industrial mold, it is important to consider the properties of the parts well.

To this end, the following are considered:

- Type of application of the piece

- How to assemble a piece in an industrial process

- Fracture resistance

- General or partial structure of the piece

- The amount of pressure or load applied to the piece

Most of the above is intended to design a piece, but these must also be considered in the manufacture and design of industrial molds of liquid silicone rubber as it has a direct impact on the mold material.

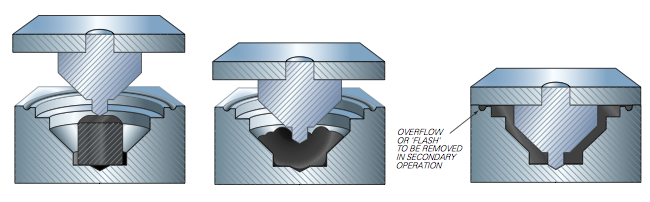

In fact, one must consider how the LSR enters the mold, the type of mold filling and the mold cooling to form the mold. In the design of industrial molding of liquid silicone rubber, usually the dimensions of the piece, the type of additives required for the liquid silicone rubber, the amount of stress and the absence of a splash are also taken into account. In addition, for good sealing of the parts, the mold should enable the LSR, which will fit the thin mold walls well with minimal challenge and adaptation.

It should be borne in mind that LSR, like other thermoplastic materials, can have different grades, such as low or high hardness, low or high elasticity, and so on.

Making LSR molds

The LSR industrial molds should include unique features. In fact, the industrial mold used for liquid silicone rubber is a more advanced and more resistant industrial mold than other thermoplastic molds.

Generally, the manufacture of industrial liquid silicone rubber molds begins with mold design by various software professionals and professionals working with these software. The design of the piece is made available to the machinists in 3D. These specialists begin the process of manufacturing LSR molds with a combination of CNC machining and the EDM process.

High temperature and high heat resistant aluminum is commonly used for the manufacture of industrial LSR molds, but a variety of stainless steel and waterproof steel may also be used. In any case, the metal used for the manufacture of industrial liquid silicone rubber molds must be capable of withstanding the heat and pressure of the LSR injection.

That’s why making these types of industrial molds generally takes a long time, and must be done with extreme precision. This is why manufacturing LSR molds is recognized as the most important and major achievement of LSR injection molding.

Due to the properties of LSRs in filling the walls, corners and thin sections of the mold, designing the industrial LSR mold in any type of design is less of a design challenge, as it fills all the spaces well.

Of course, the surface quality of the industrial mold used for liquid silicone rubber does not require very careful polishing, since after molding the mold inside the mold it is easy to remove the parts from the mold.

Not all industrial molds produced for the LSR process, however, are injectable. Sometimes casting molds are also called LSR casting molds, which are suitable for parts that have a lot of complexity in assembly. Many types of gaskets or sealing parts can be manufactured using LSR die casting molds.

The industrial molding of liquid silicone rubber also enables the production of parts for products with low or no error percentage. Using this type of mold improves the efficiency of the components, reduces assembly costs and allows the addition of other materials to the LSR.

Manufacture of parts in the molds of industrial LSR

After the LSR industrial mold is prepared, the liquid injection manufacturing process, or LIM, must be carried out to produce the various parts for which the industrial mold is designed. Keep in mind that the production of this type of parts in industrial molds is unlike other types of plastic injection methods, which use the force of pressure on the material. As these molds do not require pressure and the method Injection in these molds consists of two parts mechanical composition, in industrial mold.

In fact, the main difference between the LIM injection method and other material injection methods is the time it takes to produce the piece and deliver it. In principle, the LSR industrial mold can only be mounted on advanced injection machines, which can support LSR injection and perform precise injection volume control, and make special components with liquid silicone rubber.

Therefore, during the industrial molding of the LSR, the planning and optimization of the injection automation system must also be carried out, and in principle have the necessary settings for the injection to reach the appropriate injection volume for each component. An important point in this industrial mold design is to pay attention to customer demand. Accordingly, the plates as well as the jacks that precisely close the mold should be considered, and some factors such as temperature, pressure, injection rate, and adjustment cycle time also should be considered.

Advantages of using LSR to produce parts:

The use of liquid silicone rubber (LSR) to produce parts is becoming more and more common and used in various industries, mainly due to the immense benefits of this material, some of which are:

- The possibility of mass production and large volume of parts in a short time

- Very low contamination of this material for the environment and humans due to the production of closed cycle components

- Ability to produce components in the process of automation of injection at high levels and with great progress

- Reduce parts production time due to the possibility of accelerating parts production due to the high capability and adaptability of liquid silicone rubber

- Removing extra tasks like removing waste

- The possibility of manufacturing industrial molds from the simplest form to the most complex possible without the risk of empty space

- Ability to change injection temperature to produce different parts

- The possibility of producing different resistance components for any type of chemical or simple

- High safety for humans and the environment

Parts needed by industries such as medical equipment, automotive, consumer parts, the construction industry, electronics, parts with specific applications such as irrigation parts, pumps, industrial valves, keyboards, pockets, etc. are mainly produced today in this way.

Jamien Tarhe Parsian or JTP Industrial Group is proud to be one of the first manufacturers of advanced industrial molds, produce all kinds of molds for injection of liquid silicone rubber or industrial casting mold of liquid silicone rubber, in the simplest and most sophisticated form, and base on the customer’s needs.

JTP Industrial Molds has high warranty and long-term support, and all customers can apply any of our custom or new molds using our ability to design and customize any kind of industrial mold using our highly skilled designers with guaranteed delivery.