Concentrated pump

One of the most important types of material transfer electro pumps or material transfer pumps can be called the concentrate pump also known as mono pump. This type of pump is a type of positive displacement pump or positive pressure pump, which is often used to transport high concentrations of materials such as types of oils or liquids with different wastes, mixtures and combinations.

Concentrated pumps are also used to transport chemicals, provided that the structure and gender of the pump are proportional to the acid and chemical content. In this case, the pump is mainly known as a chemical transfer pump, and despite the many similarities in the structure of the pumps, the body type and components of the pumps used are different.

Concentrated pumps are usually made of highly corrosion-resistant structures, and are resistant to particles and solids inside liquids. For this reason, concentrated pumps can be used to transport highly concentrated materials, even materials such as sand or asphalt. These pumps have high suction and output power and are used in many industries.

As mentioned, the condensate pump can also be used as a chemical transfer pump, but the body structure and components of the pump must be tailor-made for chemicals. Concentrated pumps have many different types that we will get to know more about.

How to operate a concentrated pump

The concentrated pump or mono pump, sometimes referred to as the pulp pump, is one of the most widely used industrial pumps in the world.

Concentrator Pump works in such a way that the electromotor first circulates and circulates inside the stator using a shaft connected to the transmission and the rotor and rotor joints. By diverting the gap between the rotor and the stator, the material moves from the inlet or the feeder to the pump outlet, and this discharge or space is often filled with materials, and the pump speed is influenced by the material’s velocity.

In fact, as explained, the condensate pump is a positive displacement pump. That is, with the rotation that the engine generates at the pump, a certain amount of fluid is displaced each time it moves from the feed to the output.

Types of concentrated pumps

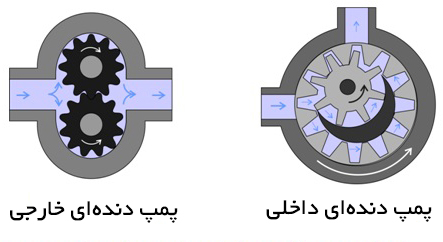

Regardless of the various names that have been marketed or known to the general public for concentrated pumps, the concentrate pump has two general types, which are divided into internal gear concentrator and external gear pump. Of course, there are also earrings, screws, and gyrator concentrator pumps, which are much more widely used in both indoor and outdoor gear and are more common.

Concentrated internal gear pump

The Concentrated internal gear pump, also known as the inner gear pump, is one of the most powerful types of material transfer pumps, which can even move very thick materials such as asphalt or sand. However, this type of material transfer pump is also used for some low viscosity materials that are large in volume. In general, the high capacity and high power of the internal gear pull pump make it possible to use this type of pump for a variety of purposes.

Consider, for example, one-hour gears that move over each other and cause other gears to rotate and eventually the clock is used, the internal gear pump and even the external gear pump based on this same pattern. , And they have two sturdy gears that rotate over each other and eventually move the machine. These gears are mounted inside the machine in the internal pump or inner gear pump.

Concentrated pumps are hydraulic pumps that operate in positive displacement and use displacement to rotate the fluid by rotating the device. In fact, concentrated pumps are suction-type in themselves, and this is due to the high power of the device. Regardless of whether or not the gasket pump gears are internal or external, this capability can carry any type of material with any viscosity.

In the case of a concentrated internal gear pump, the high suction power of the device allows it to easily move even a material with a concentration of asphalt.

Why concentrated internal gear pump?

In general, the concentrated internal gear pump can be recommended for the following benefits:

- The concentrated internal gear pump does not have a complex structure and consists of two simple yet powerful gears.

- The high power of this type of pump causes no fluctuation in its output.

- Any material of any viscosity from lowest to highest can be easily transported with this pump.

- Concentrated internal gear pump can be operated with bi-directional operation

- The maintenance cost of this type of pump is low because of its simple operation

- Easy to install.

- Has a very powerful self-suction system

- The flexibility of the concentrated internal gear pump is very high in performance.

- There is no problem with the pump when drying

- Can work unilaterally.

- Considering the type of application and function, it can be custom-made and used for any type of material. Therefore, the internal concentrate pump can also be customized for the transfer of chemicals and acidic materials.

In addition to the benefits of a concentrated internal gear pump, some considerations or limitations of this type of pump at the time of purchase include:

- Internal gear pump concentrator has limited rotational speed

- The pressure of this type of pump is limited and eventually reaches low to medium pressure.

- Excessive load on the pump may cause problems in the pump structure.

- The speed of the concentrated internal gear pump is not high, so it does not work well in industries that require high speed material handling.

Application Types of concentrated internal gear pump

Keep in mind that using an internal gear pump can be done in most industries. But the important point is that before ordering and purchasing a concentrated internal gear pump, be sure to discuss the matter with the manufacturer to determine if there is a need to change the nature, quality, or type of component or device structure.

It is important that the concentrated internal gear pump, with the necessary power and capacity, can withstand the type of material needed for transport. This means that the acidic or chemical state of some materials will easily damage some of the concentrated pump components and structures that are manufactured for non-chemical purposes.

But in general, the following industries and production goals can be achieved by using a concentrated internal gear pump:

- Transfer of high concentration industrial oils and solvents

- Transfer fuel liquids such as gasoline, diesel and so on

- Pumping and transportation of minerals and construction such as sand or asphalt

- Transfer substances such as isocyanates or polyons

- Use to transport products like chocolate in the food industry

- Transfer all kinds of polymer and resin materials in polymer industry

- For transportation of materials used in road construction

- Transfer substances like gluon

- Use in the healthcare industry to transport soap or self-soap and surfactants

Concentrated internal gear pump structure

As explained above, the concentrated internal gear pump structure can be easily customized to suit the needs of customers, especially in a manufacturing company such as Jamin Tarhe Parsian (JTP) Company. Therefore, a variety of cast iron or stainless steel or polymers can be used to make the body of the pump for the manufacture of concentrated internal gear pump. Gears are also made of steel, stainless steel and cast iron, or can be used to produce bushings of graphite, bronze, silicon carbide, ceramic, tungsten or carbon carbide, etc.

Also, the shaft material of the internal concentrator pump can be of alloys such as steel or even cast iron or stainless steel.

External gear pump

Another type of concentrator pump that has higher power and efficiency than the internal condenser pump is the concentrate external gear pump or the external gear pump. This type of pump also has two gears on each other that rotate on top of each other to transfer materials or liquids of very high viscosity and the gears of this pump are mounted outside the body of the device.

Why Concentrate External Gear Pump?

In general, the Concentrate External Gear Pump has many advantages that can easily be exploited in various industries. The following are some of the most important of these benefits:

- The price of this type of pump is very affordable

- The life of the Concentrate External Gear Pump is very long.

- External gear pump concentrator has high quality and various functions

- Made for high speed material and volume transfer

- Easy to maintain and used.

- Easily transfer different types of materials or liquids of different viscosity with better speed and performance.

Concentrate External Gear Pump Limitations

The limitations of external gear pump concentrator include the following that should be taken into account when purchasing external gear pump:

- The gears are mounted on the outside so that the pump must be installed in areas that are not contaminated or protected from contamination.

- Be careful not to touch the bearings of the machine with liquids or other materials as the bearing can be attached to other materials and this may reduce the life of the bearing.

Industries and uses for which the Concentrate External Gear Pump can be used:

Concentrate External Gear Pump can be used for most industries provided that you have the device’s structure and capabilities tailored to your needs, localization or customization. For this purpose, it is best to discuss your pump usage before finalizing your purchase with experts at JTP Company to design the pump to suit your needs.

But in general, the most important use of a Concentrate External Gear Pump can be seen in the following:

- Used to transport a variety of liquids or oils and even hot and acidic oils

- Used as a chemical carrier

- Used for transporting materials or hydraulic oils

- Used to pump acidic materials or play with different densities

- Use in environments with low or high fluid volume.

- Used in the food industry to transport substances such as chocolate or paste

External Gear Pump Concentrated Structure

As explained, in JTP company material transfer pumps such as an external concentrator pump can be manufactured for different purposes with different structures. Gray cast iron, ductile, bronze or polymer types can be used for the body structure of the outer gear concentrate pump, and the liner material can be bronze, stainless steel or carbon, etc.

The structure of the bushing or the external gear pump bushing can also be considered as bronze, stainless steel or carbon, and the shaft is made of ceramic, steel, stainless steel or a variety of alloys.

Buy Internal Gear Concentrate Pump or Choose External Gear Concentrate Pump?

One of the most important questions for our clients at JTP Industrial Group is which of the two types of material transfer pump or internal or external gear pump is best for their business or industry and which to choose.

Keep in mind that gear pumps are generally positive displacement type and convey a certain amount of material each time. Both types of pumps have uniform pulse-free flow.

The Internal Gear Concentrate Pump has a slower operating speed and provides better uniformity. Perhaps the biggest advantage of an Internal Gear Concentrate Pump is the self-suction feature of the device and can continue to work while drying, though it is not recommended.

Also another feature of the Internal Gear Concentrate Pump is that it can work two-way. This allows the pump to be used for both drainage and refilling.

Maintenance costs are low in the Internal Gear Concentrate Pump, and if they require repairs, they are easy to repair and therefore have little maintenance cost. It is also applicable to a variety of materials of varying viscosity and must be reinforced to transport chemical, oily or acidic materials.

The External Gear Concentrate Pump has more restrictions on fluid transfer than the internal Gear Concentrate Pump. The speed of fluid transfer in this pump is higher and the pressure is higher. The price of this type of pump is lower and the price is cheaper. Also, this type of pump should not be used in polluted and dusty environments.

The External Gear Concentrate Pump has much less noise than the internal Gear Concentrate Pump. Perhaps the biggest drawback of using an External Gear Concentrate Pump is that they have slightly more restriction than the internal Gear Concentrate Pump than the solid material and large particles. These particles and materials can easily damage the body and structure of the pump, and especially the gears. Although this problem is improved by restructuring, however, having a high pressure and speed increases the damage to the pump structure if these particles are present.

Therefore, it is advisable to use an internal Gear Concentrate Pump to transfer materials with solids and solids. Instead, it is better to transfer chemicals, acidic materials, and all kinds of oils, especially those materials that need to be transported quickly, to an external gear pump. It is also advisable to use external gear pumps for machine tools and hydraulic machines.

Buy Concentrate gear pump

The most important points for purchasing a concentrated pump is the type of material or fluid to be transported. In this regard, it is best to do your purchase of concentrate transfer pumps from manufacturers.

JAMIN TARHE PARSIAN Company (JTP) as the largest manufacturer of electro pumps and pumps for heavy and thick material transfer, relying on the knowledge and capability of its highly professional forces, has produced a wide range of types of gear pumps tailor-made to suit the needs of its customers.

The good thing about buying Concentrated Pump from JTP Company is that our experts thoroughly check your need before ordering, and customize your gear pump to suit the type and function of your industry, to the best type the pump has the highest efficiency and longest life.