Manufacture of industrial and complex molds

Molding is the first step to mass production of industrial parts. Molding is especially important when it comes to producing large numbers of parts. Therefore, in this case it is necessary to do the production in a high number using mold and with a special industrial process.

The more complex the industrial mold is, the more difficult it is. In addition, some parts have a high precision that requires the most delicate and highly sensitive mold. Alongside these materials, there is also the issue of the variety of parts. Some are made of plastic, some of steel, and some of all other materials, each with its own mold. Hence, molding has become a very diverse and complex process today.

Industrial mold design

Unlike in the past, the molding process was mainly trial and error and eventually produced with less precision molding, but today advanced companies such as Jamien Tarhe Parsian ( JTP) Design use highly specialized software to produce any kind of industrial mold. During the design of the industrial mold, the characteristics of the parts and their gender are also taken into account. But the most important thing in designing industrial molds is customer demand and needs.

Today, many advanced industrial machines are capable of working with diverse and complex industrial patterns. Some of these machines, such as CNC machines, have made great advances in both hardware and software. Nowadays one can easily apply the most precise and elegant industrial molds using advanced industrial machines and produce the best and most quality parts.

Using industrial mold design software requires a lot of knowledge and experience. An experienced designer takes all the principles of industrial mold design and utilizes all the software tools to implement all the mold components, to make the best mold to produce the highest quality parts.

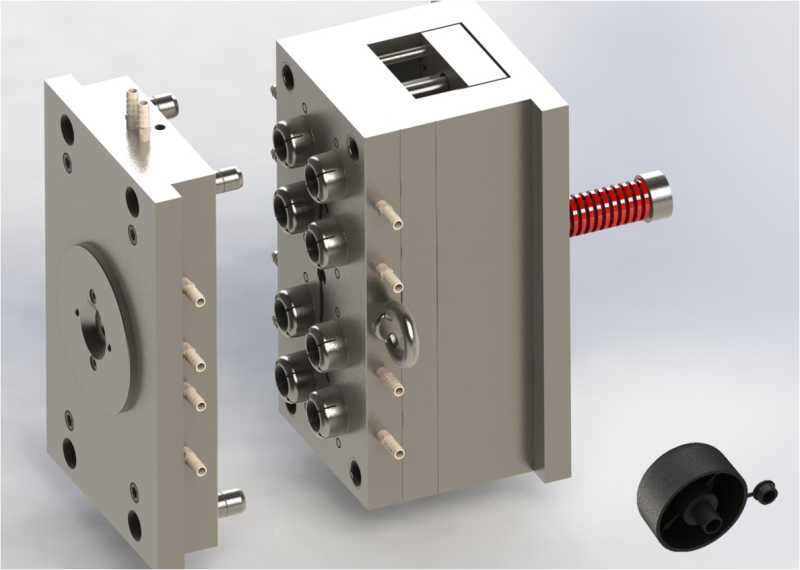

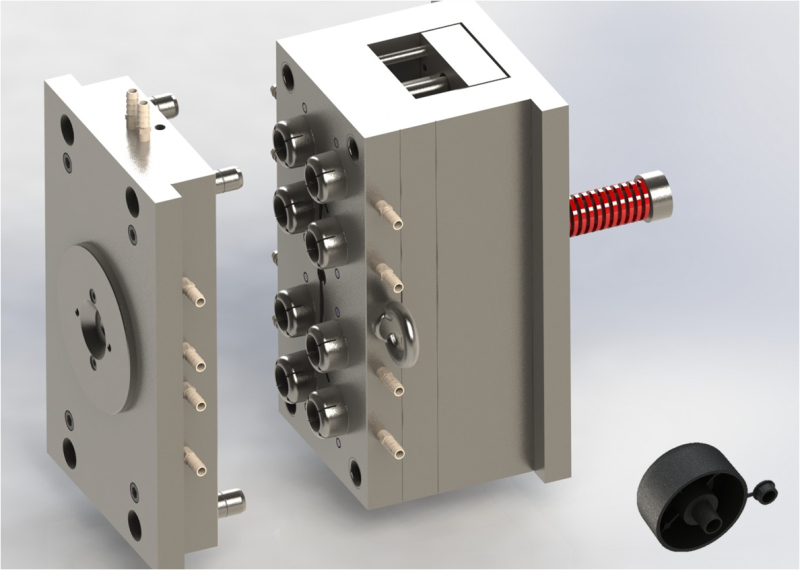

The most popular software for industrial mold design can be found in Solidworks, Mechanical Desktop, IMOLD and especially CATIA. These software are capable of defining and preparing all parts of the template in 3D. In fact, each template may have its own software or some industrial template to complete used different steps in different software.

The output of industrial mold design software is mainly a three-dimensional mold that is given to professionals for machining. In fact, this three-dimensional design is prepared by performing the industrial molding process, which is done by machines such as CNC machines and then sent to the assembly stage.

After the industrial mold is assembled, the mold is ready for sample submission. The output of this sample template determines whether the template is well designed to produce the desired piece. If changes need to be made, these changes will be applied to the software until the industrial mold design process is finalized and this industrial mold design is tailored to the client’s needs.

Types of industrial molds

As explained, industrial molds vary widely, which depend on the method of production, regardless of the material. The simpler the end specifications, the easier it is to make industrial molds, and the more complex these parts are, the more important the mold industry needs to be.

Generally, industrial molds can be classified into the following categories:

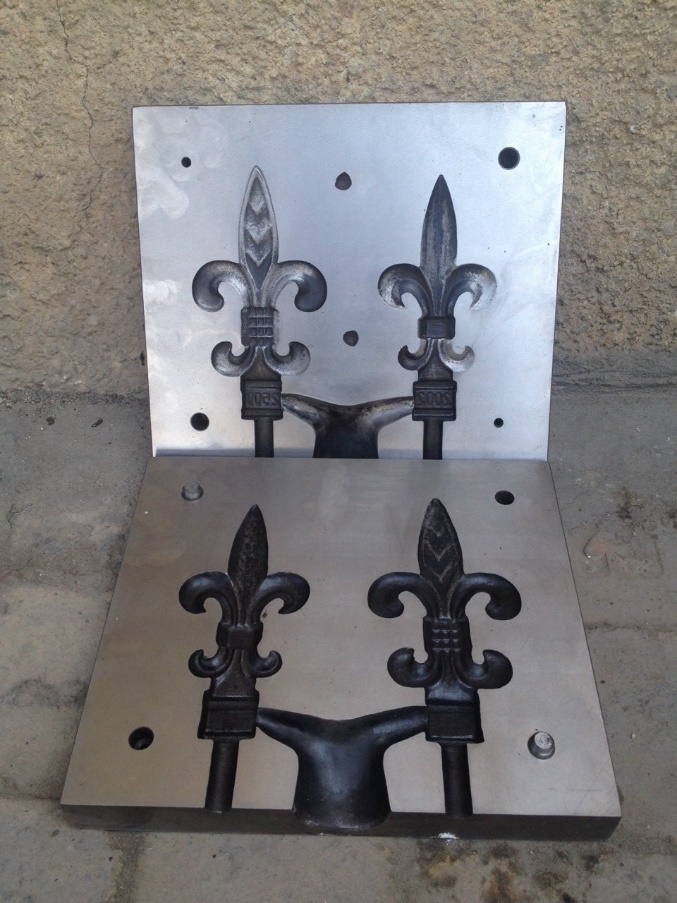

- Casting molds

Casting molds are specially made and manufactured by casting parts. To produce these types of molds, the material must be considered. So there may be a great deal of variation in the casting itself. Casting molds are divided into the following categories:

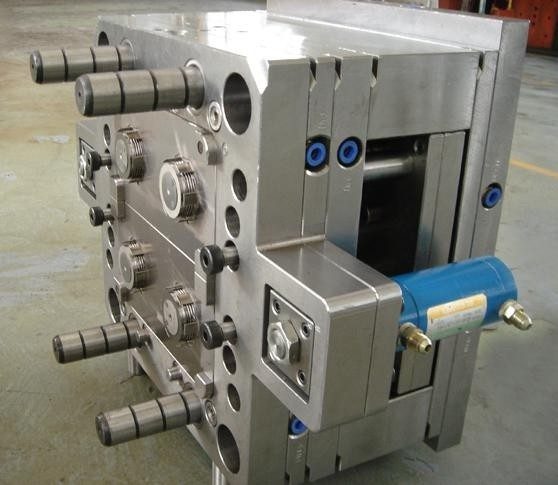

- Die casting molds

It is made of aluminum, copper or zinc and has a thickness of between 1.5 and 15 mm. Pressure casting is used to make this mold. In fact, to make this type of industrial mold, high-pressure aluminum melt is injected into the mold as mold.

One of the benefits of industrial die-cast molding is that the parts do not need to be machined and are usually produced without smoothing. This type of industrial die cuts production costs because of the speed at which the work is completed and the need for some other operations. These types of molds are made of high thickness stainless steel with high pressure tolerance and therefore the price of die castings is usually high. Die cast molds are also called high pressure molds.

- permanent mold (gravity method)

Permanent molds, also known as low or low pressure molds, are used to produce metal parts such as aluminum, zinc, copper and so on. These types of molds are mostly specialized in the production of parts of different thickness and strength of the piece. Permanent molds usually produce parts without microporous or porosity.

The pressure also means that the injection in these molds is done slowly. These industrial molds are smaller and lighter than die casting molds, but they are more complex because of their gating system design. That is why they need to be more difficult to design and have better knowledge and technology, which in turn increases the price of the parade mold.

- Sand mold

Sand mold known as Sand cast molding is the third type of casting molds used to produce metal parts. A metallic model made of a sand mold is used to make the sand mold. In fact, the metal is melted into sand to produce the piece. Usually, metal models are used for a variety of casting purposes. Some molds are used for automatic die casting (DIZA) and some are used for traditional and manual processes.

– Plastic injection molds

Mold making with plastic is one of the most versatile and widely used industrial molding methods. Plastic injection molds are commonly used to make and design plastic molds. Manufacturing a plastic injection mold is first designed by industrial mold design software and then a plastic injection mold is prepared.

There are mainly two types of plastics or materials used to produce plastic molds, which are thermoplasts or thermostats.

Thermoplasts are a type of plastic material that bends in the heat and hardens as they heat away. Usually no special chemical changes occur in this type of material, which is why, after plastic injection, the mold chamber is shaped.

To make these molds, they first fill the mold with heat-treated material and inject it into the mold chamber. Because the mold is cold, these materials immediately take the form of mold.

Thermostats are unlike thermoplasts. That is, these materials become hard to heat and actually undergo chemical changes. In this type of molding, the material is cold and the mold is also cold. In this method, the material is first injected into the mold in the same cold state and after the mold is filled, the mold is heated to obtain the material of hard plastic shape and structure. However, in order for the materials to fit well into the mold, they are usually pressed at a temperature of 170 ° C.

This allows the thermostats to first be crushed and then molded. The most important feature of this type of material is that it is disposable and cannot be reused after hardening.

Advanced and modern industrial molds

Manufacturing and production of advanced and modern molds using stainless steel, heat resistant and abrasive is one of the specialty of Jamin Tarhe Parsian Company. Nowadays, advanced industrial molding machines need to be used to produce some different parts such as pet and disposable containers, wall molds or rubber injection molds.

The most important of these types of advanced molds include pre-made molds, special injection molds for synthetic rubber and silicone, special high-speed thin wall molds, and a variety of industrial molds for plumbing, sealing, etc.

Steps for manufacturing industrial molds

We said that the most basic step for industrial mold making is mold design, which is mainly done by different software today. Therefore, the industrial mold manufacturing process should be divided into mold design and manufacturing.

The industrial mold design section described above. It is mainly the basic requirement of mold making and the more accurate the design, the better the industrial mold.

For the purpose of industrial manufacturing, they incorporate the three-dimensional model produced in the design as the basis of the industrial process. CNC machines are the most common of these types. The mold is then assembled after machining.

Keep in mind that some molds may be produced in one piece and others may be individually produced and assembled. Once the assembly is complete, production begins. To do this, machining of wood molding components is done by CNC milling machine. The design given by the designer runs on the machine computer.

After approval of the manufactured piece, the sample will be sent to the casting department to produce industrial molds depending on the type and type of parts required for production in the casting or forging section to suit customer requirements. When the industrial molding is completed, the industrial mold is ready for mass production.

Note that each of the molds may vary greatly and be known by other names.

Manufacturing of industrial molds requires the necessary technology and high knowledge and expertise. At Jamin tarhe Parsian Company (JTP), we bring together a full suite of expertise, advanced and sophisticated machinery, valuable workforce and know-how in industrial production to help you produce the best sample of industrial molds for any type of industry.

Our commitment is to make industrial molds tailored to customer needs and wants. So you can contact our experts to request the best type of industrial mold in Iran and experience quality products.